| Availability: | |

|---|---|

| Quantity: | |

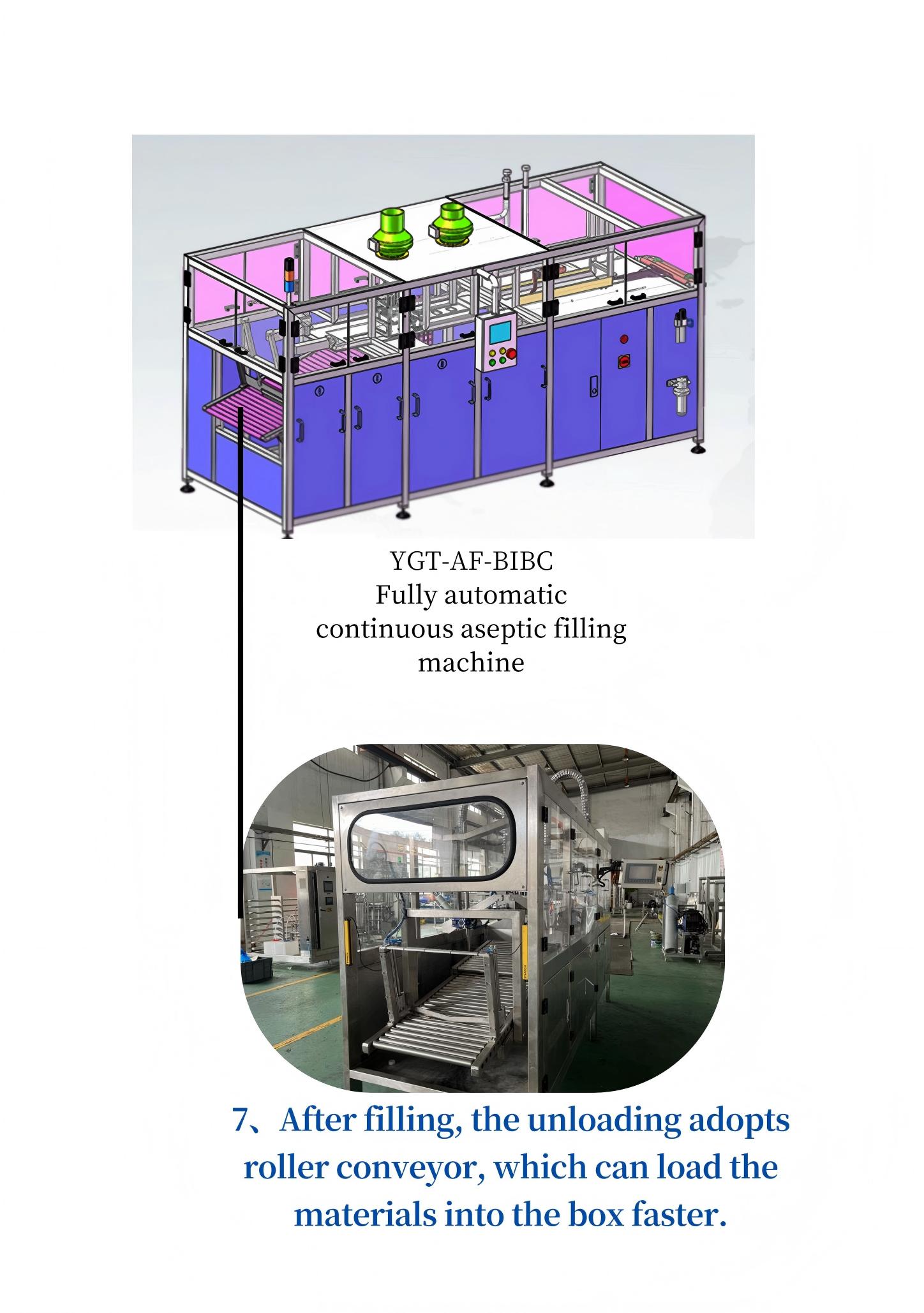

Product Description

The Fully Automatic Continuous Aseptic Filling Machine is a state-of-the-art solution designed for high-volume aseptic filling of linked bag-in-box (BIB) containers. It integrates the entire packaging process—from bag feeding and uncapping to vacuumizing, quantitative filling, and capping—into a single, fully automated workflow. This machine is engineered for medium to large-scale production operations, delivering exceptional throughput while maintaining strict sterile packaging standards. Its continuous bag design compatibility and smart control system make it a versatile choice for industries requiring efficient, labor-saving liquid packaging, ensuring products retain freshness and quality without refrigeration. Whether handling beverages, dairy, sauces, or chemical liquids, this continuous aseptic filling machine sets a new benchmark for productivity and reliability.

Configuration

The machine completes bag delivery, uncapping, filling, capping, and bag separation automatically, eliminating manual intervention and reducing labor intensity. This seamless process ensures consistent packaging quality and maximizes production efficiency.

Engineered for continuous bag chains, the machine supports various bag sizes, enabling uninterrupted filling for high-volume operations. It adapts easily to different product lines, making it ideal for multi-product manufacturing facilities.

Integrated CIP/SIP systems and sterile processing zones ensure that every container meets strict hygiene standards. Nitrogen flushing options further enhance product preservation by preventing oxidation, extending shelf life without preservatives.

Equipped with advanced flowmeters or weighing systems, the machine delivers exceptional filling accuracy, minimizing product waste and ensuring consistent volume per container. The Siemens PLC control system allows for precise parameter adjustment and real-time process monitoring.

The machine features low power consumption and minimal product loss during cleaning and operation. Its durable construction and easy maintenance design reduce long-term operational costs, delivering excellent return on investment.

|  |  |

Technical parameter

BlB Aseptic filler occupies a large area, is suitable for large-scale production, and can maintain precise aseptic filing in high-speed operations.

Using continuous bag packaging materials, continuous filling is achieved through automatic bag feeding structure.

BlB Aseptic filer has a high degree ofautomation and can automatically complete the entire process of bag delivery, fiing, sealing,bagging and output, etcimproving production efficiency and reducing labor intensity.

| Model | YGT-LBIB-1 | YGT-LBIB-2 |

|---|---|---|

| Filling Heads | Single-head | Double-head |

| Filling Volume | 1L – 25L | 1L – 25L |

| Capacity | 180–220 bags/hour (5L) | 350–400 bags/hour (5L) |

| Filling Accuracy | ±0.3% | ±0.3% |

| Control System | Siemens PLC + HMI | Siemens PLC + HMI |

| Air Supply | 0.6–0.8 MPa | 0.6–0.8 MPa |

| Power Supply | 220V/380V, 50Hz | 220V/380V, 50Hz |

| Material | SS304/316L | SS304/316L |

| Optional | CIP, SIP, Remote Control | CIP, SIP, Remote Control |

Note: Capacity and configuration can be customized based on customer requirements.

Application

Perfect for filling fruit juices, tea, energy drinks, plant-based milks, and alcoholic beverages (wine, spirits), maintaining their natural flavor and quality. Suitable for UHT milk, condensed milk, cream, and yogurt base, ensuring sterile packaging that preserves nutritional value and freshness.

Ideal for tomato paste, ketchup, soy sauce, vinegar, and sugar syrups, providing hygienic packaging that extends shelf life and simplifies transportation. Applicable to fruit concentrates, herbal extracts, and nutritional supplements, delivering precise filling and sterile packaging for high-value products. Meets the requirements for filling chemical liquids, pharma intermediates, and cleaning fluids, ensuring safe and sterile packaging for industrial and medical applications.

Service

Our Fully Automatic Continuous Aseptic Filling Machine leverages the latest in automation technology to streamline your production line, reducing labor costs and increasing throughput. We offer 24/7 technical support via email, video call, and optional on-site service within 72 hours. Our multilingual documentation ensures easy operation worldwide.

We tailor the machine to your specific bag sizes, filling volumes, and product requirements, ensuring seamless integration with your existing production infrastructure. Built with food-grade stainless steel and international-quality parts (Siemens PLC, Festo pneumatics), the machine delivers reliable performance and long service life. The machine meets global standards (CE, FDA, GMP) and provides full process traceability, ensuring your products comply with industry regulations and audit requirements.