| Availability: | |

|---|---|

| Quantity: | |

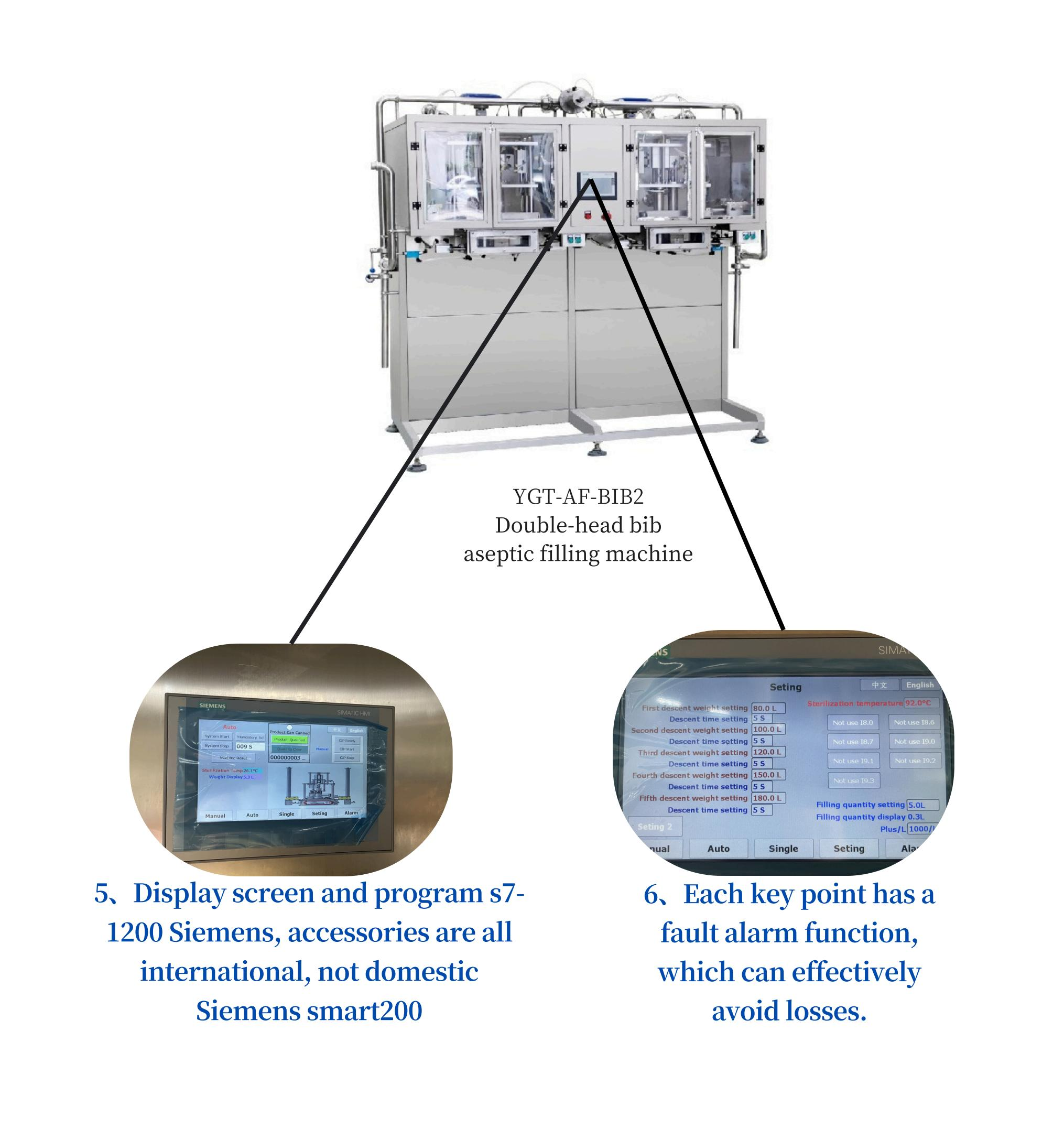

Double-head BlB Aseptic Filler

YGT

Product Description

The Double-head BIB Aseptic Filler is an advanced filling solution designed for high-efficiency, sterile packaging of liquid food products into bag-in-box containers. It is widely used in the dairy, juice, beverage, and liquid food industries. Featuring two independent filling heads, it supports simultaneous or alternate filling, significantly enhancing productivity while ensuring aseptic integrity throughout the filling process.

Configuration

The double-head setup enables simultaneous or alternate filling, significantly boosting production throughput without compromising aseptic integrity. This flexibility allows for seamless adaptation to varying production demands, reducing downtime and maximizing operational efficiency.

Equipped with CIP/SIP systems and sterile air filtration, the machine creates a contamination-free environment for filling. It ensures that every bag-in-box container meets strict food safety standards, eliminating the risk of spoilage and extending product shelf life without refrigeration.

The Siemens PLC control system paired with an intuitive HMI touch screen provides full automation of filling volume, temperature, and flow rate. Operators can easily adjust settings, monitor processes, and access fault alarms, minimizing human error and ensuring consistent filling accuracy.

Crafted from SUS304/316L stainless steel, the machine features smooth surfaces, sanitary pipe connections, and minimal product retention areas. This design not only simplifies cleaning and maintenance but also resists corrosion, ensuring long-term reliability in harsh production environments.

The machine supports a wide range of spout bags with different cap types (gland or screw), accommodating various packaging needs from small to large volumes. Tool-free adjustments enable quick bag size changeovers, enhancing operational flexibility for multi-product lines.

Technical parameter

The Double-head BIB Aseptic Filler is a cutting-edge solution tailored for the aseptic packaging of liquid food and beverage products into bag-in-box (BIB) containers. Engineered to meet the strict hygiene and efficiency demands of modern production lines, this machine integrates advanced aseptic technology with dual independent filling heads, delivering reliable performance for businesses of various scales. It eliminates the need for refrigeration by maintaining sterility throughout the filling process, extending the shelf life of products while preserving their original quality, flavor, and nutrients. Whether handling dairy, juices, syrups, or other liquid foods, this aseptic filling machine ensures consistent results with minimal product loss, making it a cornerstone of efficient liquid packaging operations.

| Item | Parameter |

|---|---|

| Filling Capacity | 200–500 bags/hour (depending on size) |

| Bag Volume Range | 1L–25L |

| Filling Accuracy | ± 0.5% |

| Filling Head | Double-head, independent control |

| Sterilization Method | Steam-in-place (SIP), CIP ready |

| Control System | Siemens PLC + Touch Screen |

| Flowmeter Type | Electromagnetic or Mass Flowmeter |

| Material of Construction | SUS304 / SUS316L |

| Power Supply | 380V / 50Hz / 3Ph (customizable) |

| Air Consumption | 0.6–0.8 MPa, 0.3 m³/min |

| Steam Consumption | 50–80 kg/h (for sterilization) |

Application

Ideal for UHT milk, cream, condensed milk, and yogurt base. The machine preserves the nutritional value and freshness of dairy products through sterile filling.

Suitable for fruit juices, tea, energy drinks, and plant-based milks. It maintains the natural flavor and color of beverages without the need for preservatives.

Perfect for filling fruit concentrates, sugar syrups, and other viscous liquid ingredients. Ensuring consistent quality for food and beverage manufacturing.

Applicable to tomato paste, purees, broths, and other liquid foods, providing hygienic packaging that extends shelf life and simplifies storage.

Meets the strict sterility requirements for oral liquids, health tonics, and non-viscous nutritional supplements. Adhering to pharmaceutical-grade standards.

Service

Our Double-head BIB Aseptic Filler is built with international-quality components, including Siemens PLC and premium stainless steel. To ensure stable performance and minimal maintenance.

We offer tailored design solutions to match specific bag types, filling volumes, and product requirements. Ensuring the machine integrates seamlessly with your existing production line.

Our team provides on-site installation, operator training, and 24/7 online after-sales support. We also offer remote diagnosis and a steady supply of spare parts to keep your operations running smoothly.

The machine meets international food safety regulations, including GMP and FDA requirements. Ensuring your products are market-ready worldwide.

By reducing product loss, minimizing labor involvement, and eliminating refrigeration costs. The machine delivers long-term cost savings while boosting production capacity.